Jul. 02, 2025

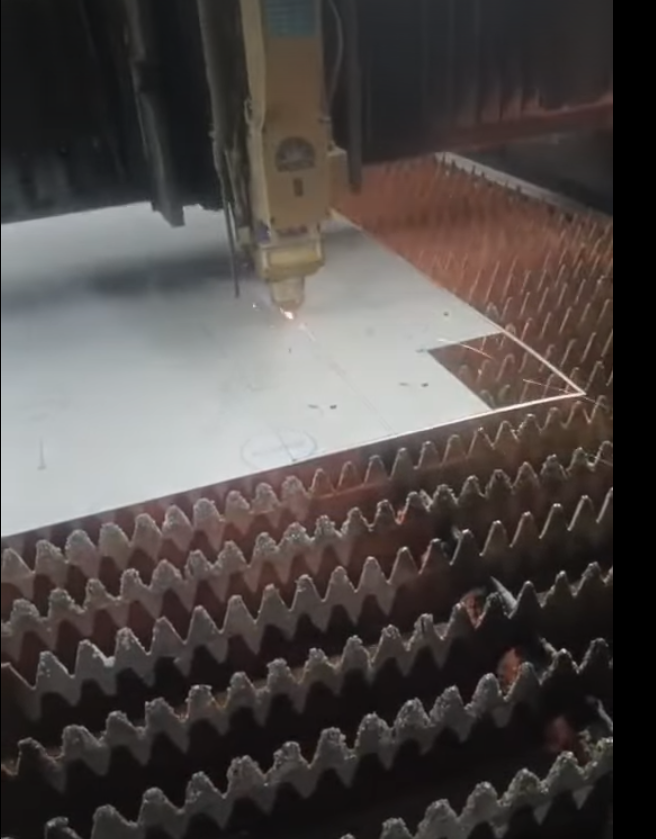

Laser protection films play a crucial role in safeguarding sensitive surfaces during laser processing. Whether you are working with fiber lasers or CO₂ lasers, selecting the appropriate protective film is vital to ensure clean processing, prevent surface damage, and optimize production efficiency.

Fiber and CO₂ lasers differ significantly in their wavelengths, power densities, and applications, which directly impacts the type of protective film required. This guide will provide a detailed comparison of laser protection films designed specifically for fiber and CO₂ laser machines, helping manufacturers and fabricators make informed decisions.

Fiber lasers operate at a wavelength of approximately 1.06 micrometers (µm), using a fiber-optic cable doped with rare-earth elements as the gain medium. They are highly efficient, compact, and ideal for metal cutting, welding, marking, and engraving.

CO₂ lasers emit infrared light at a wavelength around 10.6 µm. These gas lasers are well-suited for cutting, engraving, and marking non-metal materials such as wood, acrylic, plastics, glass, and fabrics, as well as some metals.

During laser processing, sparks, molten material, and heat can damage the surface of workpieces. Laser protection films shield the surface from scratches, contamination, and thermal damage. However, the choice of film must correspond to the laser type to resist:

Heat and thermal stress specific to the laser wavelength

Chemical interactions from processing fumes or molten residue

Mechanical abrasion from sparks or debris

| Parameter | Fiber Laser Protection Film | CO₂ Laser Protection Film |

|---|---|---|

| Wavelength Compatibility | Optimized for 1.06 µm, blocking specific laser reflections | Optimized for 10.6 µm wavelength |

| Heat Resistance | High, often >200°C to withstand dense metal cutting sparks | Moderate to high, depends on processed material |

| Adhesive Type | Silicone or acrylic adhesives designed for residue-free removal at high heat | Acrylic adhesives, sometimes modified for plastic substrates |

| Film Thickness | Typically thicker (50–100 microns) for durability against sparks | Can vary; thinner films often used for delicate plastics |

| Durability | High abrasion resistance for metal processing | Flexible and conformable for diverse material types |

| Chemical Resistance | Resistant to metal oxides and fumes | Resistant to plastics and organic vapors |

| Surface Finish | Smooth, anti-static for precise laser work | Glossy or matte finishes depending on application |

Cutting stainless steel, aluminum, titanium

Welding automotive or aerospace parts

Marking metals with high precision

For these applications, the laser protection film must endure high temperatures, mechanical abrasion, and chemical residues from molten metal. Films with silicone-based adhesives and high temperature resistance (up to 260°C) are recommended. Thickness above 70 microns provides sufficient durability.

Engraving and cutting acrylic, wood, leather, textiles

Glass etching and marking plastic components

Fabric and foam cutting

Protection films for CO₂ lasers focus on chemical compatibility with plastics and flexibility. Acrylic adhesive films that peel cleanly without damaging softer surfaces are preferred. Film thickness can range from 30 to 70 microns depending on substrate fragility.

Heat and Thermal Stability: Laser processing generates localized heat spikes. The film’s backing and adhesive must maintain integrity without melting, bubbling, or discoloring.

Adhesive Performance: A critical feature is clean removability to avoid adhesive residue that can degrade final product quality or require costly cleaning.

Compatibility with Substrate: The film must bond well without damaging powder-coated, painted, or polished surfaces beneath.

UV and Environmental Resistance: Especially for outdoor or prolonged storage applications, UV resistance helps maintain film performance.

Match Film Properties to Laser Type: Ensure the film is specifically tested for either fiber or CO₂ laser wavelengths and power levels.

Consider Your Substrate Material: Metal, glass, plastic, or composite materials may require different adhesive formulations.

Evaluate Film Thickness: Balance durability with conformability; thicker films resist sparks better but may be harder to apply on complex geometries.

Check Manufacturer Technical Data: Look for thermal resistance, adhesive type, thickness, and peel test results.

Perform Trial Runs: Before full-scale production, test films under actual laser conditions to verify performance.

Multi-layered films: Enhanced heat and abrasion resistance with controlled adhesive release.

Eco-friendly formulations: Solvent-free adhesives and recyclable backings.

Custom printing: Branding or part identification integrated into protective films.

Smart coatings: Anti-static, anti-fingerprint, or self-healing surfaces.

Choosing the correct laser protection film for your fiber or CO₂ laser machine is essential to protect surfaces, optimize processing quality, and reduce post-processing labor. Fiber lasers demand thicker, high-temperature resistant films with strong adhesion, while CO₂ lasers benefit from flexible, chemically compatible films tailored for plastics and non-metals.

By understanding your laser system’s characteristics and material requirements, you can select a protection film that maximizes efficiency and product quality.

For trusted laser protection film solutions engineered for both fiber and CO₂ laser machines, rely on NB Technology—your partner in innovative surface protection and processing materials.

Navigation

+86 158 1691 5404

+86 757 8271 3937

+86 757 8271 3937

No. 10 Industry Huacongsiyue Village, Shishan Town, Nanhai District, Foshan, Guangdong Province, China